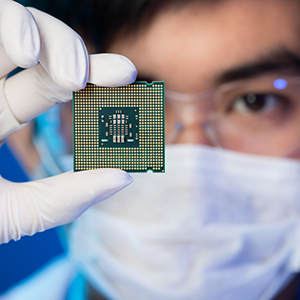

In recent years, a number of high-performance, multifunctional system LSIs have been developed by miniaturization of processes and development and automation of design tools. At the same time, a wide range of knowledge and high technical skill is required for test development and evaluation work of system LSI. In addition, higher cost of corresponding test systems, related equipment, jigs etc., and increase in test cost due to prolonged test development etc. have become conspicuous. In this situation, our company has comprehensive services related to the testing of system LSI.